Zhixin, which prides itself as a pioneer in specialized wear-resistant materials and ferroalloy machineries and equipment research, development, production and renovation, is unrivalled. In addition to making the performance of different machines better, it also ensures that they last longer especially under harsh conditions.

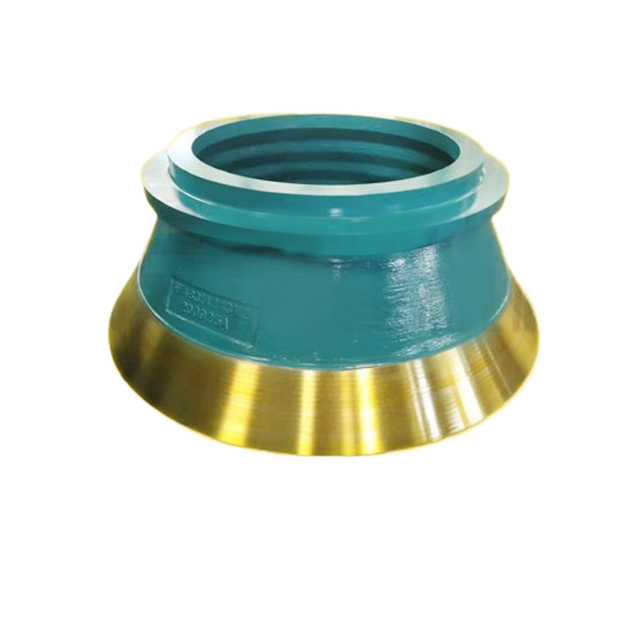

Bowl liners play a crucial role in crushing industries as these are usually subjected to serious rubbing wearing out. Crushing equipment’s efficiency as well as service life can be influenced significantly by their design and material. The making of Zhixin bowl liners was done meticulously so that they can last longer than any other during crushing process involving reactive materials. With respect to our bowl liners at Zhixin, we provide clients with economically viable solutions that will ensure minimal down times, constant crushing levels and increased lifespan for their products.

Our commitment to innovation and quality comes through in every single bowl liner produced. We have continuously been exceeding industry requirements through incorporation of advanced manufacturing techniques and use of high-quality input materials. Being an established supplier for solutions within ferroalloy sector among others associated with its application field, reliability when it comes to bowl liner terms has become synonymous with Zhixin name.

Chengdu Zhixin Refractory Technology Co., Ltd. was established in March 2016 and is located in Chengdu Cross-Strait Science and Technology Industrial Park, Wenjiang District, Chengdu City. The company focuses on the research and development, production and repair of complete sets of machinery and equipment for special wear-resistant and high-temperature-resistant materials and ferroalloy industries. Committed to the promotion and application of wear-resistant material technology. It is an innovative technology enterprise and full-stack solution service provider that integrates scientific research, production, sales and empowerment. The company currently has 42 products in 5 categories of wear-resistant materials, and has 6 core formulas of wear-resistant and temperature-resistant materials.

The company utilizes patented products employing new technologies and processes, resulting in significant cost savings for users.

While creating value, the company also contributes to economic development strategies focused on energy conservation, emissions reduction, and carbon neutrality.

The company is a full-stack solution provider specializing in wear-resistant and high-temperature resistant materials.

Under equivalent conditions, the lifespan of our company's products is 1-3 times longer than similar products in the market.

20

May

20

May

20

MayA bowl liner is a wear-resistant component used in machinery and equipment for industries that deal with special wear-resistant and high-temperature-resistant materials and ferroalloys. It is designed to protect the inner surface of a bowl-shaped structure from abrasion and damage.

Bowl liners provide several benefits, including protecting the inner surface of bowl-shaped structures from wear and damage caused by abrasive materials. They enhance the efficiency and lifespan of machinery and equipment, reducing the need for frequent repairs or replacements.

In most cases, bowl liners can be repaired or replaced when they become worn or damaged. However, the feasibility of repair or replacement depends on the extent of the damage and the specific design of the machinery or equipment. It is advisable to consult with the manufacturer or a qualified technician for guidance on repair or replacement options.

Bowl liners may require regular inspection and maintenance to ensure optimal performance. This may include monitoring wear levels, checking for damage or cracks, and following recommended cleaning and lubrication practices. It is advisable to refer to the manufacturer's guidelines for specific maintenance requirements.