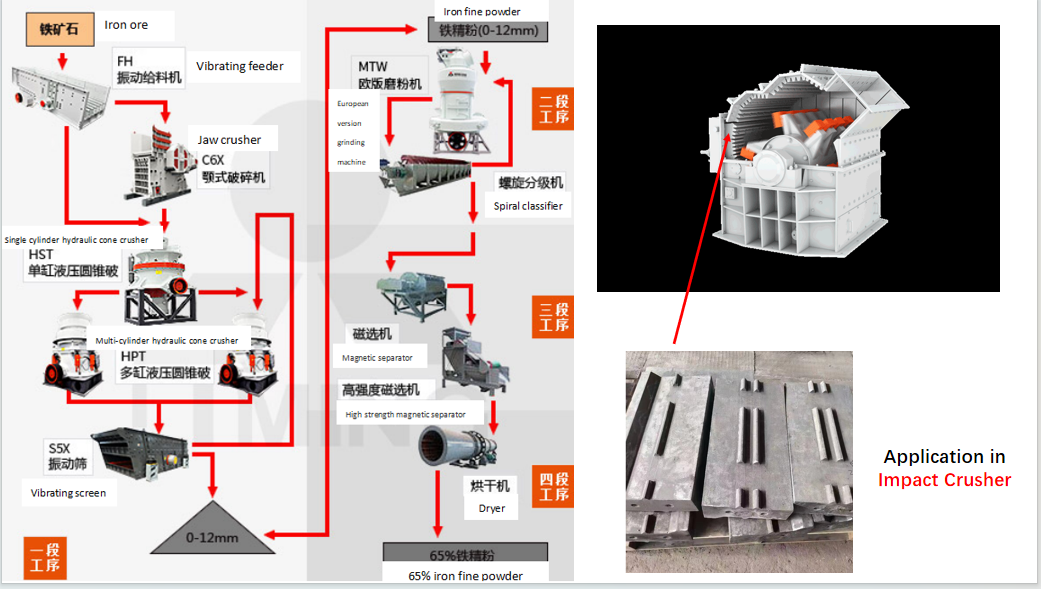

1. Raw material preparation

The process starts with the iron ore raw material, which is evenly and continuously fed into the subsequent processing equipment through a vibrating feeder. This step ensures a stable supply of raw materials and lays a solid foundation for subsequent processing.

2. Coarse and fine crushing

Jaw crusher: The raw material first enters the jaw crusher for coarse crushing, breaking the large iron ore into smaller particles for subsequent processing.

Cone crusher: The iron ore after coarse crushing enters the cone crusher for fine crushing. Single-cylinder hydraulic cone crusher (HST) and multi-cylinder hydraulic cone crusher (HPT) are used here to further crush the iron ore to a smaller particle size through multi-stage crushing.

3. Classification and screening

Spiral classifier: The finely crushed iron ore is classified by a spiral classifier to separate ores of different particle sizes for more refined mineral processing.

Vibrating screen: The graded iron ore enters the vibrating screen for screening. Through the screening effect of the screen, the iron ore that meets the particle size requirements is separated and prepared for the next step of selection.

4. Magnetic separation and selection

Magnetic separator: The screened iron ore enters the magnetic separator for magnetic separation. The magnetic separator uses the characteristics of magnetic substances in iron ore to separate it from non-magnetic substances such as gangue minerals, and initially improves the grade of iron ore concentrate.

High strength magnetic separator: The iron ore that has undergone preliminary magnetic separation enters the high strength magnetic separator for deep impurity removal and selection, further improving the purity and grade of iron ore concentrate.

5. Ball milling and classification

Although the ball mill is not directly mentioned in the picture and the original description, in similar iron ore processing processes, the ball mill is often used to finely grind the iron ore after magnetic separation to obtain finer iron powder. Subsequently, the particle size is classified again by the classifier to ensure that the particle size distribution of the final product meets the requirements.

6. Drying and finished products

The selected iron ore concentrate enters the dryer for drying to remove excess moisture and ensure the dryness and stability of the product. Finally, 65% iron ore concentrate (0-12mm) is obtained as the final product output.