Super wear resistance: The service life is 25 times longer than that of ordinary Q235B material, significantly reducing maintenance costs.

High impact toughness: ensures stable operation under moderate impact conditions and increases ball mill output by more than 5%.

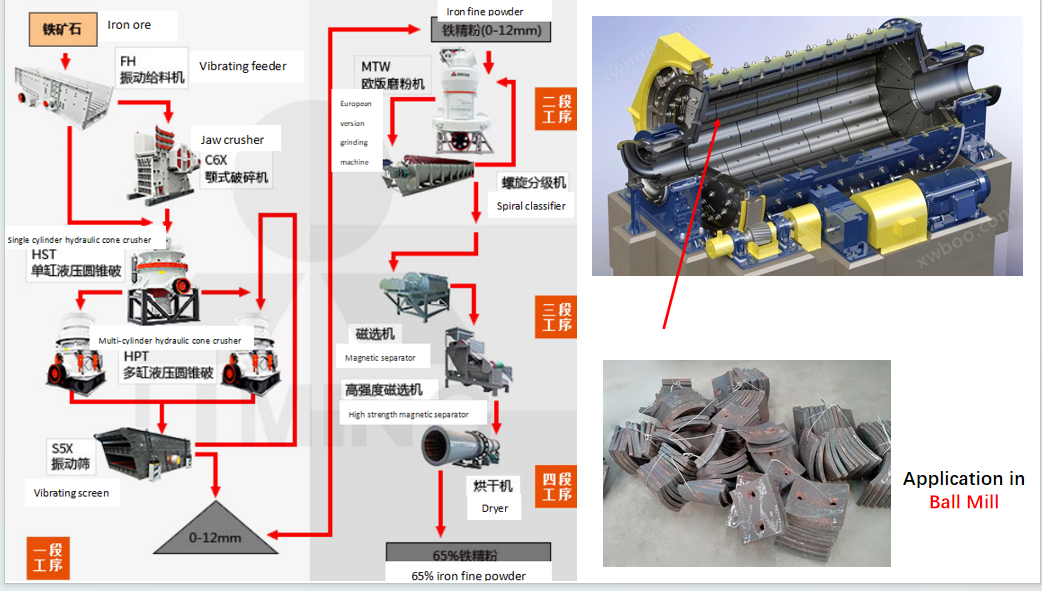

Widely used: Suitable for industries such as cement, silicate, building materials, refractory materials, fertilizers, mineral processing and glass ceramics.

Multi-layer structure design: improves wear resistance and facilitates processing and installation.

Technical specifications: The alloy components are carefully blended, with a hardness of HRC 70-73, excellent wear resistance, strong impact resistance, and good processability.

1. Technical characteristics

High wear resistance: Made of high-quality high manganese steel or alloy steel, and through a special heat treatment process, the lining plate has extremely high wear resistance and can withstand the impact and friction of the grinding body and materials for a long time.

Strong impact resistance: The lining plate is reasonably designed and has a solid structure, which can withstand huge impact forces, ensuring that it is not easily damaged during the operation of the ball mill.

Easy to install and maintain: The liner design takes into account the convenience of installation and maintenance, making it convenient for users to replace and repair, reducing maintenance costs and time.

Diversified selection: According to different models and production needs of ball mills, a variety of specifications and models of lining plates are provided for users to choose from to meet the needs of different production scenarios.

2. Advantages

Improve grinding efficiency: High-quality lining plates can reduce energy loss during the grinding process and improve grinding efficiency, thereby speeding up the production of iron ore powder.

Reduce maintenance costs: The wear-resistant lining can significantly extend the service life of the ball mill and reduce the frequency and cost of replacing the lining.

Improve product quality: A stable grinding environment helps produce iron ore powder with uniform fineness and high quality to meet the market's demand for high-quality products.